SA-1AF

SA-1AF

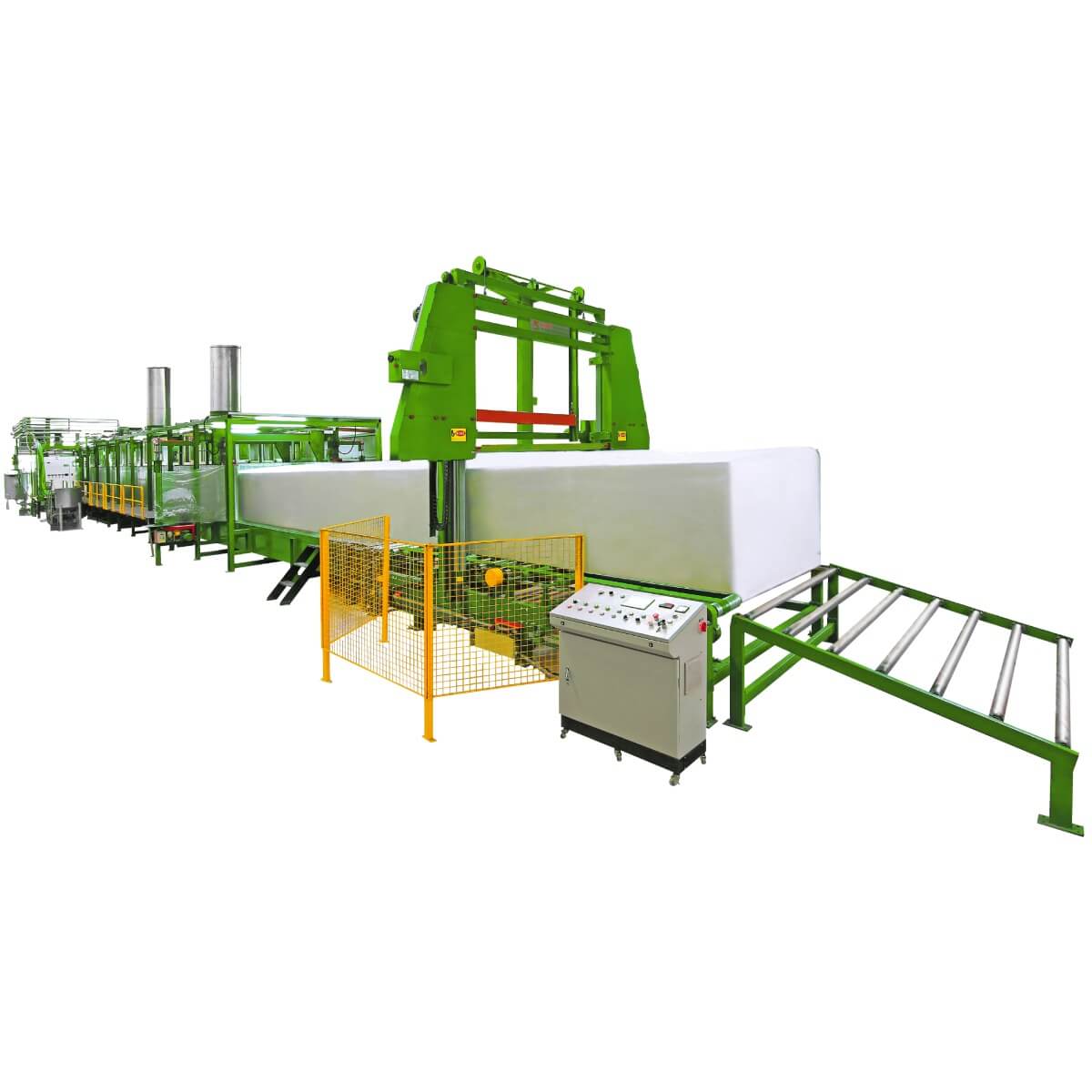

Flexible Slabstock Foaming Machine

The SA-1AF is a continuous foaming machine for the production of flexible polyurethane slabstock. Our standard model is 28 meters in length, with all necessary chemical capacities for polyol, TDI, silicon, amine, stannous octoate, methylene chloride, water, air, etc. to enable foaming output of 280 kg/min. Machine add-ons make output of up to 650 kg/min possible—send an inquiry to our Sales team today.